The driveshaft is a very interesting component that is important for a vehicle's drivetrain system - responsible for transferring power from the engine to the wheels. While often hidden from view, it plays a vital role in enabling smooth and efficient propulsion. While these are well-known facts, many don't know how it exactly works, but likely we will take a closer look at exactly that down below!

What is a Driveshaft?

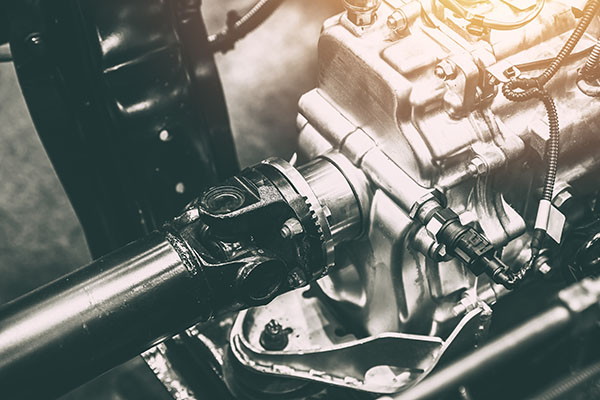

The driveshaft, also known as a propeller shaft, is a cylindrical metal tube that connects the transmission or transfer case to the differential, allowing power to be transmitted to the wheels. It is found in rear-wheel drive, all-wheel drive, and four-wheel drive vehicles.

Components of a Driveshaft

A driveshaft typically consists of several key components:

- Tubing: The main body of the driveshaft, usually made of steel or aluminum, provides structural strength and rigidity.

- Universal Joints: These flexible joints connect the driveshaft sections, allowing for angular movement and compensating for changes in drivetrain geometry.

- Slip Yoke: Located at one end of the driveshaft, the slip yoke slides in and out of the transmission or transfer case, accommodating changes in length due to suspension movement.

- Center Support Bearing: In longer driveshafts, a center support bearing is used to provide additional support and reduce vibrations.

- Flanges and Yokes: These connect the driveshaft to the transmission, differential, and wheels, ensuring a solid connection.

How Does the Driveshaft Work?

When the engine generates power, it is transferred through the transmission or transfer case to the driveshaft. As the driveshaft rotates, it transmits this rotational force to the differential, which then distributes the power to the wheels. The universal joints allow the driveshaft to flex and accommodate changes in drivetrain angles, ensuring smooth power transfer even as the suspension moves.

Balancing and Vibration

The driveshaft must be precisely balanced to minimize vibrations. Imbalances can lead to unpleasant vibrations, especially at higher speeds. Driveshafts are carefully manufactured and balanced to ensure optimal performance and minimize vibrations.

Maintenance and Repair

While driveshafts are designed to be durable, they may require maintenance or repair over time. Regular inspections for signs of wear, such as damaged universal joints or worn center support bearings, are essential. If vibrations, clunking sounds, or excessive play are observed, it is crucial to have the driveshaft inspected and repaired by a qualified technician.

Noticing any issues should send your right to a reputable repair shop just like ours! Mancinelli's Auto Repair Center invites you and your car, so the mechanics can take care of it and get you back on the road ASAP!